Benefits that Structural Foam Molding Provides to a Business

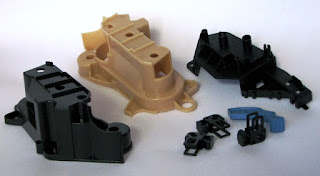

Nowadays, in most of the manufacturing industries, the process of injection molding is being used for making different plastic products, but as a manufacturer, you should know that there are many molding methods and therefore it's important to opt for the most suitable mode of manufacturing. Here, we are talking about the Structural Foam Injection Molding, which is one of the most effective services provided by the China Casting Orlando. It is a manufacturing method in which two components (polyol and isocyanate) are mixed in an appropriate ratio to form polyurethane. That prepared mixture is then injected into the structural foam mold along with an inert gas to build the required product. To know the main benefits of the Structural Foam Injection Molding, read the information given in the blog. Build large & intricate parts easily: Whether you need to build intricate plastic products or the parts of a large size, this will be the most appropriate method for you